About low/slow speed granulator

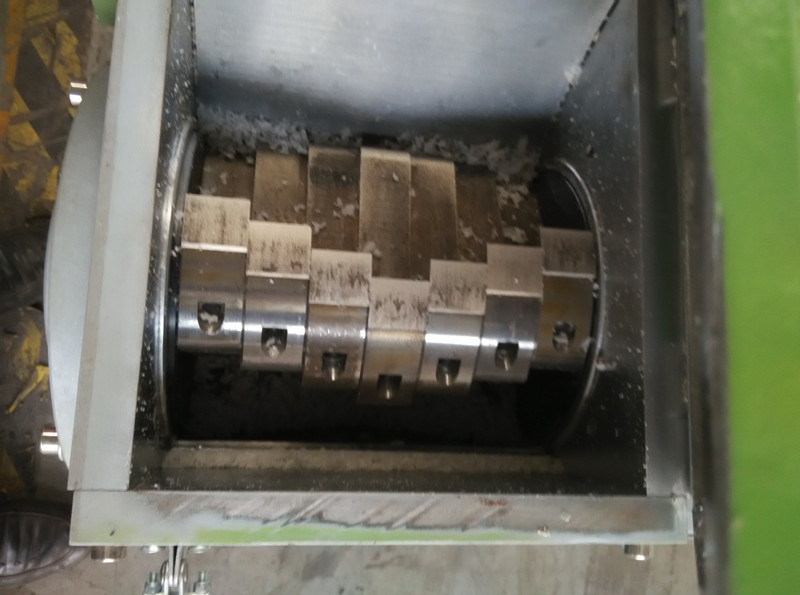

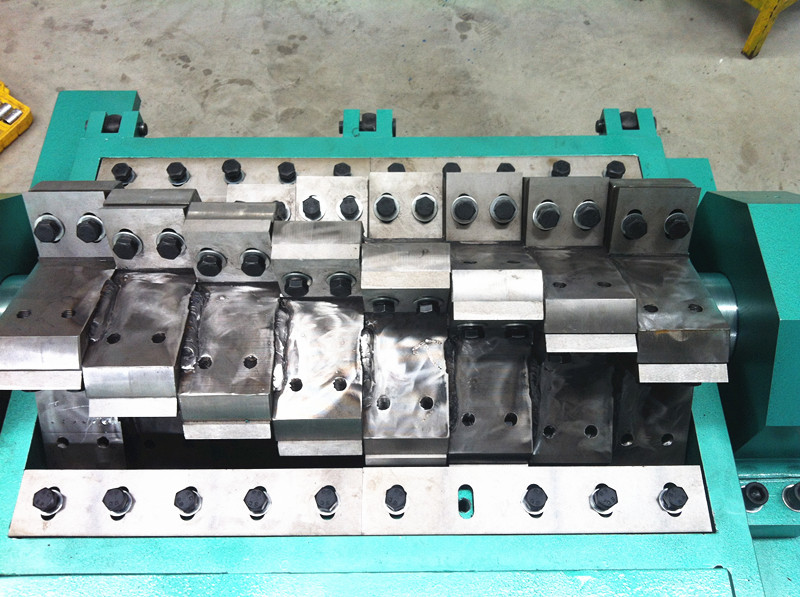

In Optima China, we offer many different granulators according to your specific industrial needs. Our low speed granulator has steel structure body, cast steel blade rest and the material of the blade is Cr12MoV. The blade adopts stepped distribution which can improve the cutting force and enhance working efficiency. Movable screen and dismounting convenience are easy for cleaning and changing. Sound insulation interlace is used in the feeding mouth to reduce the noise level and improve the working environment. A limited switch is installed in the feeding mouth to protect the operator's safety.This low speed granulator is specially used for recycling of material head, leftover material, scraped injection molding and PET bottles. Low speed crusher can improve work efficiency matching with Injection molding machine.

Technical data of low/slow speed granulator

| Model | Motor Power | Main Shaft Speed | Hopper Size | Capacity | Blade Material | Rotor Dia. |

| OGL1812 | 1.5KW | 320rpm | 130*180 | 8~15kg | Cr12MoV | Φ180 |

| OGL1821 | 2.2KW | 320rpm | 220*180 | 10~20kg | Cr12MoV | Φ180 |

| OGL1830 | 3KW | 320rpm | 310*180 | 25~40kg | Cr12MoV | Φ180 |

| OGL1840 | 5.5KW | 320rpm | 410*180 | 45~60kg | Cr12MoV | Φ180

|

Main Feature of low/slow speed granulator:

1. Low power consumption, low operating noise and little dust pollution.

2. The blades are distributed in steps, which can increase the cutting force and improve work efficiency

3. High-quality gear motor provides stable performance and long-life work.

4. Electrical protection system to protect the safety of machines and personnel.

5. Movable screen, easy to disassemble, easy to clean and replace.

6. The feed port is equipped with a limit switch to protect the safety of the operator

7. Small size, with casters, easy to move