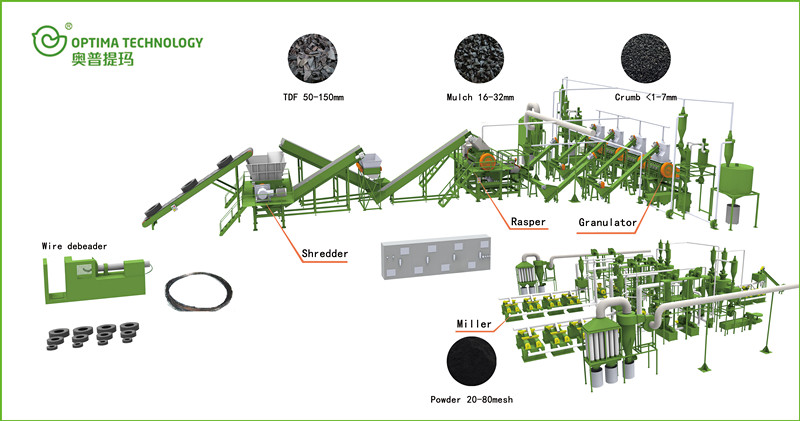

The main equipment of Tire Shredding Machine System are:

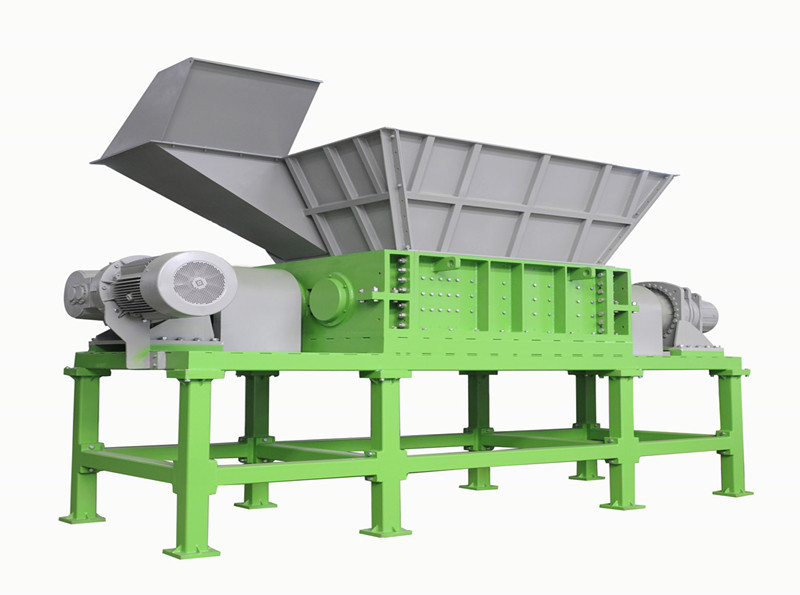

Double Shaft Shredder

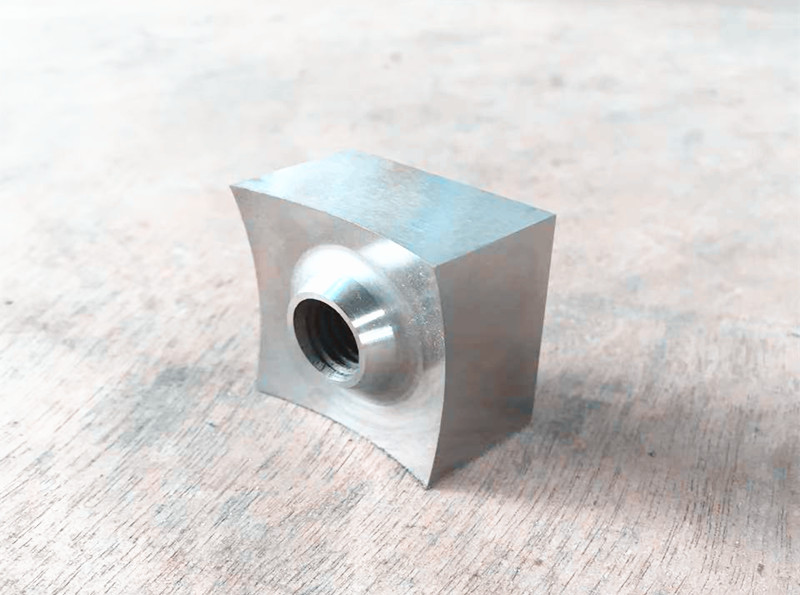

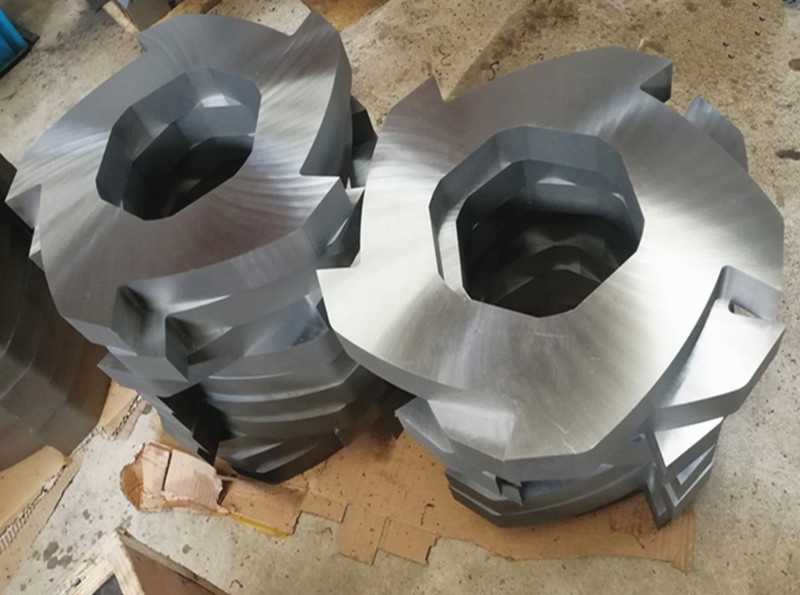

Blade

Heavy Duty Granulator

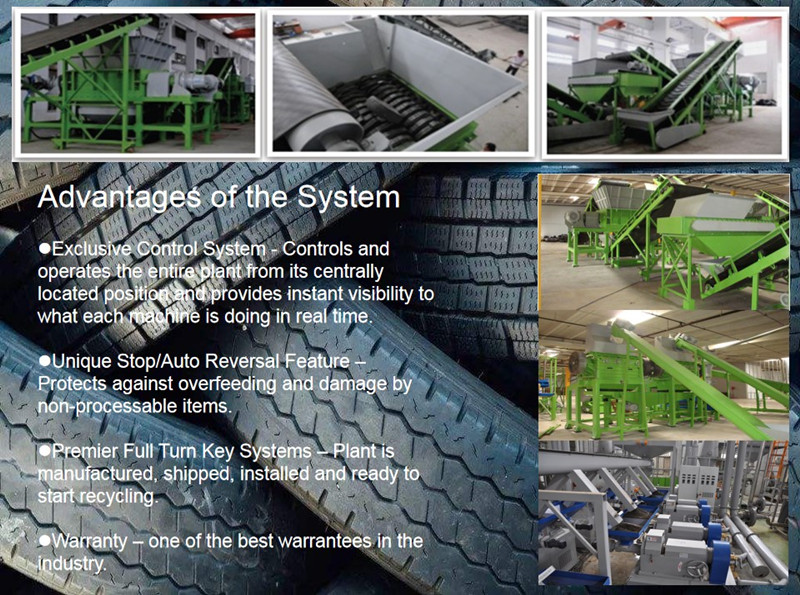

This TDF plant is different from mobile tire shredder TDF, this is designed for shredding waste tire into 50mm~150mm rubber blocks, shredder works with trommel screen, this works with disc classifier,so the capacity is increased a lot,the max. capacity up to 7 tons per hour.

The function of disc classifier,to separate over size rubber chips from required size rubber chips.

The blade adopts design of bigger smaller knives,it can cut more than 6000 tons of car tires or 4000 tons of truck tires.

We have detailed drawing and video to tell you how to replace the blades if they are worn out.

We purchase famous brands of motors and gearboxes to ensure the safety and long time life of the shredder.

Portable shredder applications

You can find more tire recycling machines and recycling equipment from Optima. Optima will always provide the most cost effective solution for end-of-life tires.

1. 50*50 mm TDF chips that can be used as fuel.

2. TDF chips can also be produced by the wire free mulch plant into 18-30mm wire free rubber granules and steel wire for Pyrolysis, gardens, playgrounds, and horse arenas.

3. Then the rubber crumb machine produces wire free rubber granules into 1-6mm rubber granules for mats, runways and playgrounds.

4. Further crushing rubber granules into rubber powder by rubber powder production line for construction and transportation applications.

FAQ:

Q1:Can you offer the OEM and the R&D product?

A:OEM & ODM are available by engineering team with 15+ years experiences.

Q2:What is the main feature of your shredder?

l Be designed with an aggressive low RPM, high torque shredding technology.

l All of our blades are made from exotic steel and heat treated to an average 56-60 on the Rockwell Scale.

l Each shaft is driven by its own Siemens motor, giving it plenty of power to drive through tires and thick steel beads.

l Customized capacity can be up to 20tons per hour