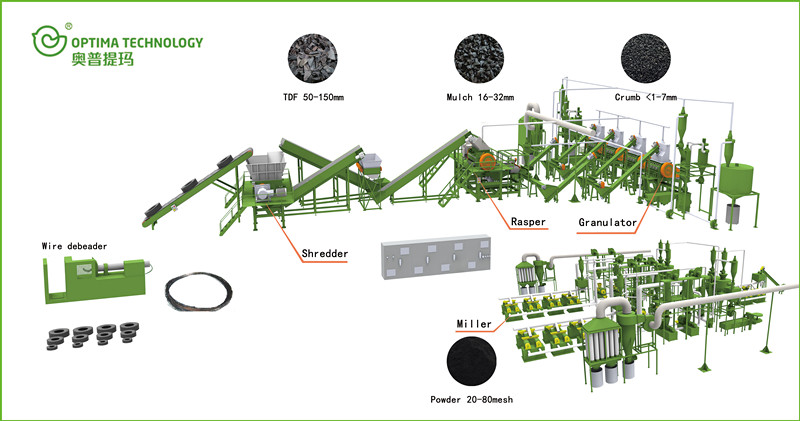

The rubber crumb plant produce a fine wire free rubber granules that can be used for remanufactured rubber, floor mats, mud flaps, sporting arenas, molded products, modified asphalt and more.

The equipment of rubber crumb machine are:

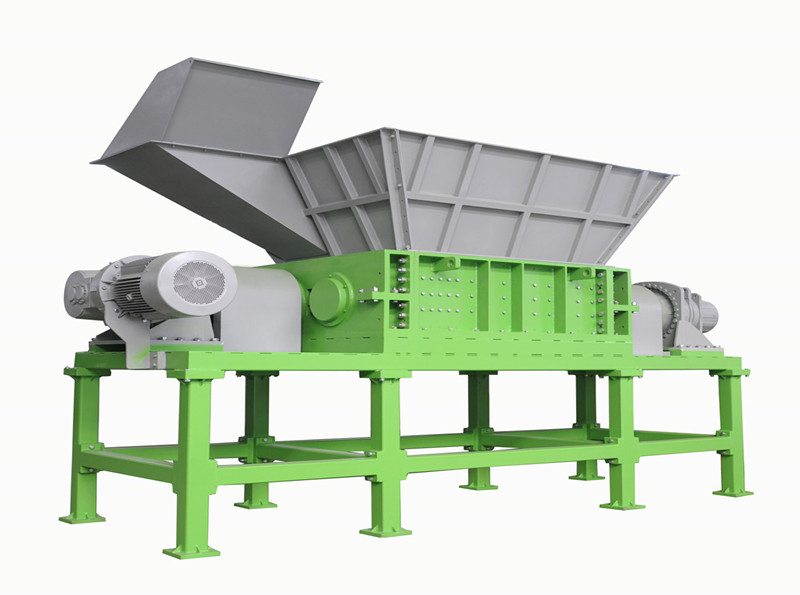

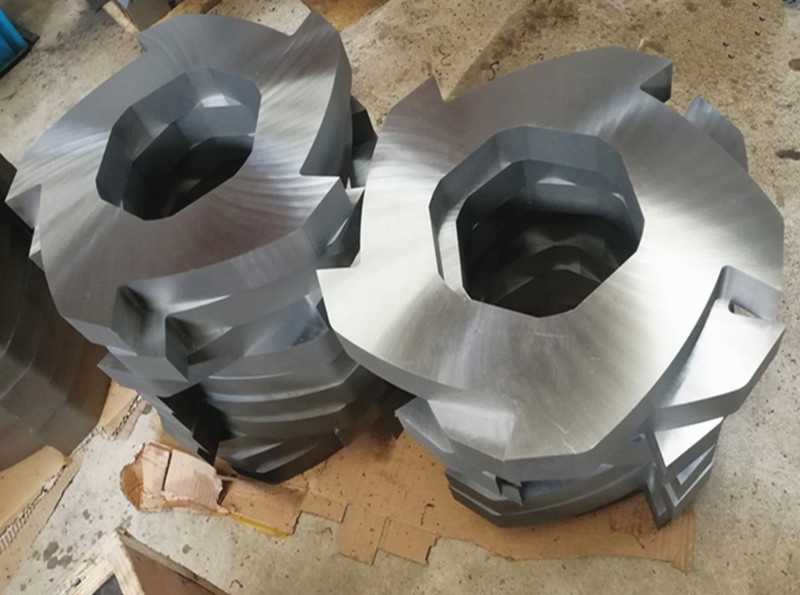

Double Shaft Shredder, Blade, Heavy Duty Granulator

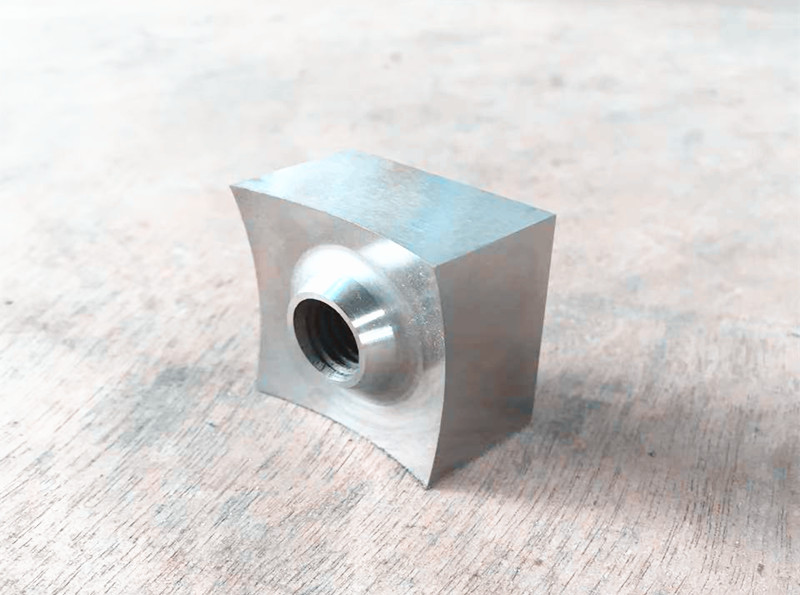

The main equipment is granulator,the Granulators are designed to grind the rubber mulch from the Grater into small granules as fine as 10 mesh. The granules are screened and re-circulated until the desired size is reached. Due to the design of the our granulator and precise alignment of the blades, this Granulator produces a very uniform cut, high quality granule. During the granulation process, 99% of the fiber is removed, leaving a contaminant free crumb rubber granulate ready to be further processed or sold.

Granulator

•Feeding : Rubber Mulch, size: 3/8" to 2" (10 to 50mm)

•Output : Grade 2 - Crumb Rubber / Granulate / Ground Tire Rubber (GTR) with the size range between 4 to 18 mesh (1 to 5 mm)

Application: rubber floor,rubber mat,rubber playground

FAQ:

Q1: What’s the main feature of your granulator?

l 99% fiber removed.

l Adjustable screen.

l Due to the design of the Granulator and precise alignment of the blades, the granulator produces a very uniform cut and high quality granules.

Q2: Do you know the purchasors of outfeed?

A: Yes, we have some market resource info,we’d like to share them with you after you become one of our customers.

Q3: Will you send the engineer to guide installation?

A: Yes, according to the customer's requirement, engineers will be sent to guide installation,commisioning and training.

Q4:Which country have you exported to?

A: USA,Puerto Rico,Spain,UK,Kazakhstan,Morroco,India,Oman,Colombia,etc.

Q5: Which brand of motor will you use?

A: China top brand Wannan or overseas brand Siemens,ABB,etc. Your requirement is acceptable.

Q6:About the after-sale service, how can you solve the problems occurred of your overseas customer in time?

A:The warranty of our machine is normally 12 months, during this period, we will arrange the international express immediately, to make sure the replace parts to be delivered as soon as possible.