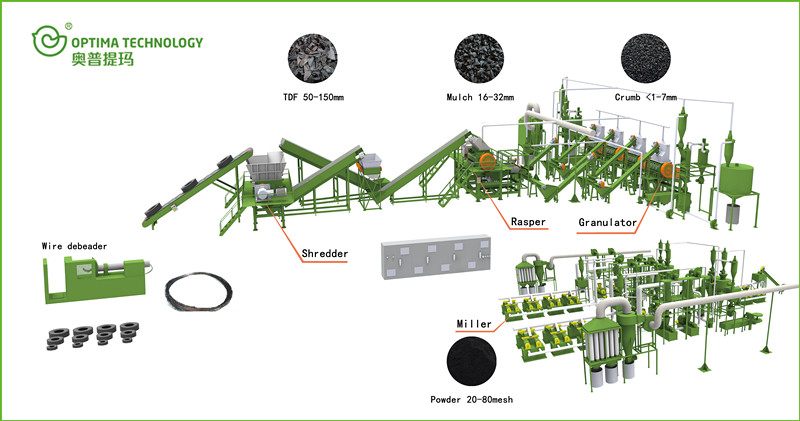

Wire free rubber mulch recycling plants for those where need wire free TDF or rubber mulch. The rubber mulch market is growing at more than 30% a year. Primary uses are for gardens, playgrounds, and arenas,offering an eco-friendly solution for disposal.

Infeed material: TDF rubber block or whole tires

Outfeed product: 18-30mm wire free rubber granules, steel wire

Main equipment: grater/rasper

Tires/Clean Cut Chips / Grater / Rasper

Feeding : TDF rubber blocks

Output : Tire Chip / Rubber Mulch / Ground Tire Rubber (GTR) with the size range between 3/8" to 2" (10 to 50mm) and free from exposed wire and textiles. (ASTM 6114, PAS 107:2012)

Application: horserace,arena playground

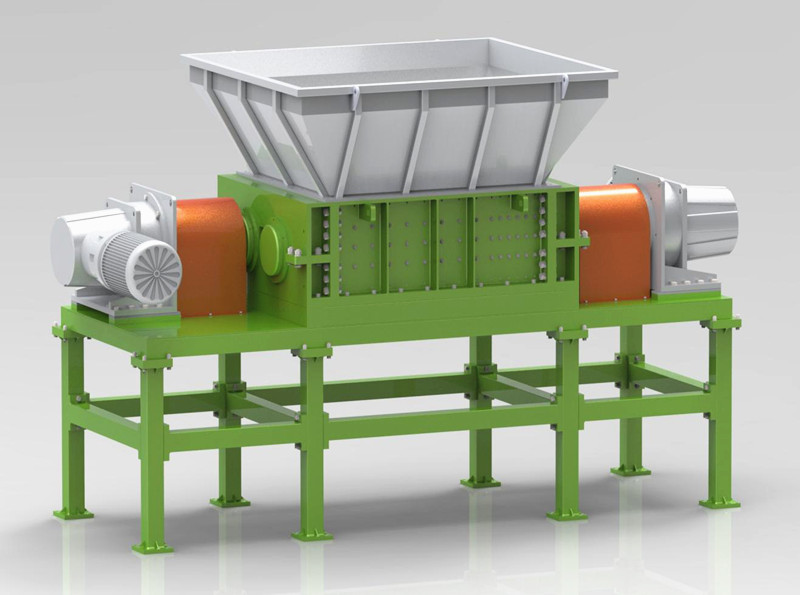

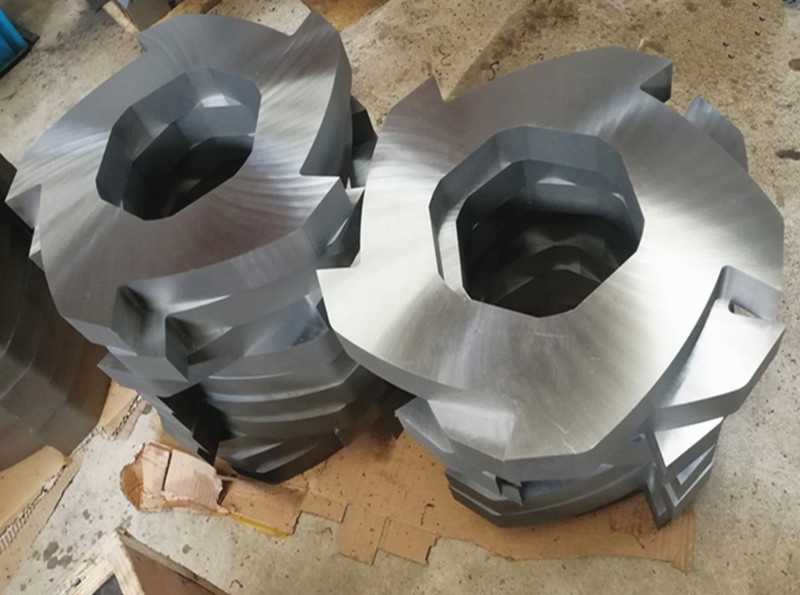

The Grater is the ultimate machine for mid-stream grinding and steel separation. It is specifically designed to take pre-shredded tires chips and produce between 18-30mm wire free rubber chip. The Grater and can process up to 5 tons of input per hour. The main rotor housing is equipped with replaceable wear plates to increase the durability and longevity of the cutting chamber. Another unique feature of this machine is the ability to turn the knives once before having to send them to be sharpened or replaced, minimizing operating costs.

FAQ:

Q1:What’s the main feature of your rasper?

l Steel separation.

l Adjustable screen.

l The main rotor housing is equipped with replaceable wear plates to increase the durability and longevity of the cutting chamber.

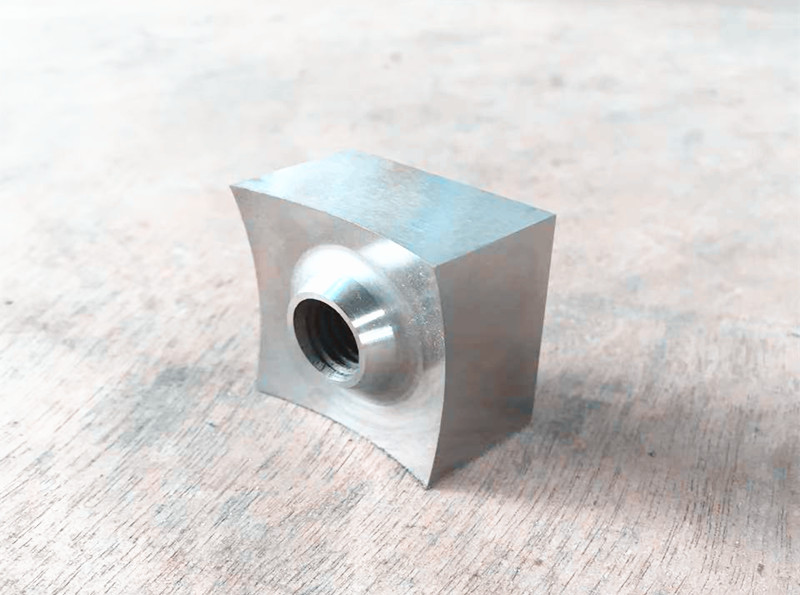

l The ability to turn the knives once before having to sent them to be sharpened or replaced, minimizing operation costs.

Q2:What make you different from your competitors? Why are you better?

l Engineering and technology very good

l Good history of quality and service

l Construction accurate

l Welds good

l PLC control,very easy operation

l Turnkey service include design,production,logistic,customs,installation,commissioning,etc.

Q3:Which country have you exported to?

A: USA,Puerto Rico,Chile,Spain,Morocco,UK,Russia,Kazakhstan,Oman,India,etc.

Q4:Why your price so expensive?

l Technology

l Material of blade

l Blade life

l After-sale service