1. Machine: Cable Granulator

2. Capacity: 200~300kg per hour

3. Online support and video support always provide

4. If customer has limited budget,the bag dust removal is recommended;

If customer wants a more automatically plant, the pulse dust removal is recommended.

5. OTD400 is a promotional model , it is very suitable to middle-scale recycling company,especially in China because of the attractive price

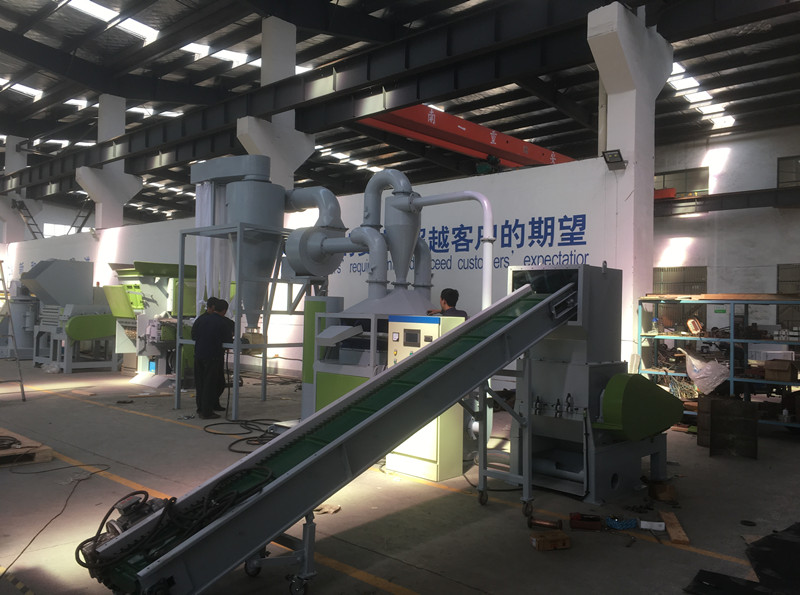

6. Welcome to our factory to check the running machines.

7. Parameters:

| Model | Capacity (Kg/Hr) | Total Power (Kw) | Weight(Kg) | Dimension(m) |

| OTD400 | 200-300 | 60 | 6600 | 6*3.5*3.2 |

8. The D2 blades work long time to save customer replacement cost,as we know, some suppliers use 9CrSi blade,it is worn out very fast.