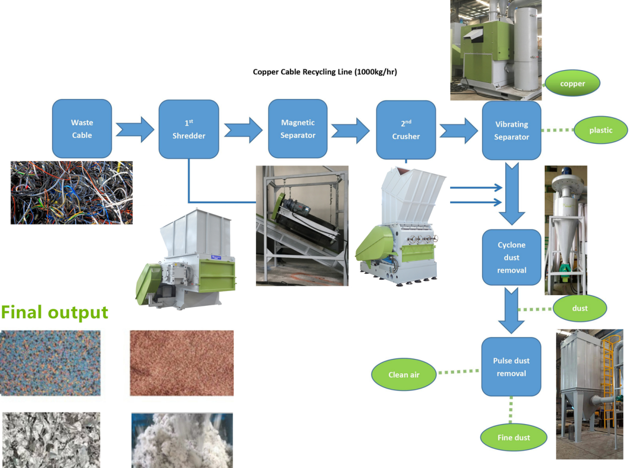

These are copper granules and plastic granules after separation, the purity up to 99.9%.

We have enigeers team to provide site service and online service, if necessary, we can send engineers to your site for installation, debugging and

training your workers.

FAQ:

Q1: How do I know the quality of your machine?

A: You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. We also warmly welcome you to visit our factory to test our machine personally.

Q2: When we only purchase one shredder machine production line, can we use it to shred other scrap materials like?

A: It is advised to show us the other scrap materials first,our team will evaluate and tell you if it is feasible.

Q3: Which brand of motor will you use?

A: China top brand Wannan or overseas brand Siemens,ABB,etc. Your requirement is acceptable.

Q4: Will you send the engineer to guide installation?

A: Yes, according to the customer's requirement, engineers will be sent to guide installation,commisioning and training.

Q5: Does crusher unit cooling be required?

A: We adopt EU technology for crusher, it doesn’t require water cooling unit.

Q6: Can we feed armoured cable?

A: The pre-shredder is advised before crusher,so that iron/steel can be removed before materials go through the crusher.