Shredders are essential machines in the recycling industry, used to break down various materials into smaller, manageable pieces. Among the various types, single shaft and double shaft shredders are the most commonly used. Though both serve the purpose of material reduction, they differ significantly in their structure, application, and operation process. Understanding these differences can help you choose the right shredder for your specific needs.

1. Machine Structure is Different

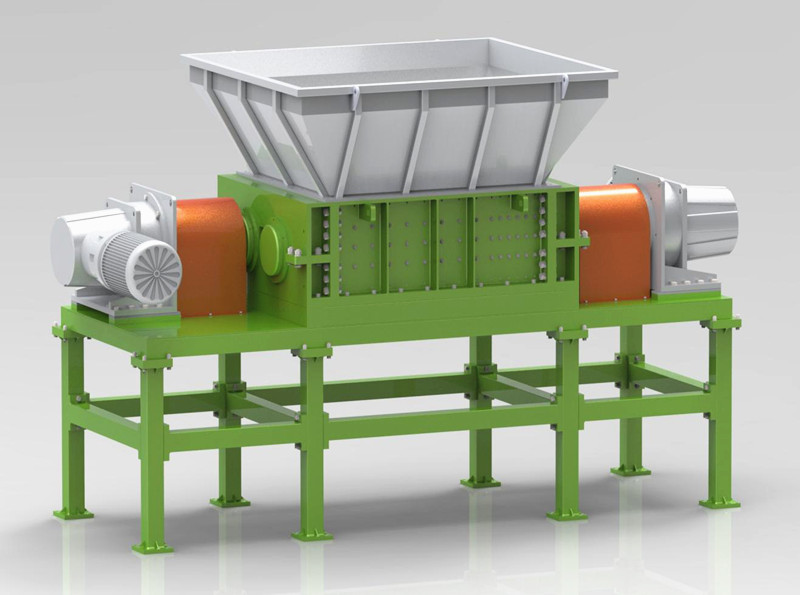

The most fundamental difference between a single shaft shredder and a double shaft shredder lies in their structure. Single Shaft Shredder is equipped with only one shaft with rotary blades, a hydraulic-driven pusher plate/arm, and a screen underneath the rotating shaft. Double Shaft Shredder is built with two shafts of blades, which we also call dual shearing shafts. There is no hydraulic-driven pusher or screen on this machine.

2. The Application of Material is Different

A single shaft shredder is generally used for shredding softer materials, such as plastic, rubber, wood, and paper. It excels at producing uniform particle sizes, which makes it ideal for applications where consistent output is crucial, like in recycling facilities or in the production of refuse-derived fuel (RDF).

On the other hand, a double shaft shredder is more suitable for heavy-duty applications. It is commonly used to shred tough and bulky materials like metal, tires, construction debris, and industrial waste. The twin rotors provide the necessary force to tear through these difficult-to-shred materials, making the double shaft shredder a preferred choice for industries that deal with more robust materials.

3. Operation Process is Different

The operational processes of single shaft and double shaft shredders are distinct as well.

In a single shaft shredder, the material is fed into the machine, where it is pushed towards the rotor by the hydraulic ram. The rotor blades then cut the material into smaller pieces. The shredded material is passed through a screen, which ensures that only pieces of a certain size exit the shredder. This process allows for precise control over the output size but can be slower if the material is particularly tough.

In contrast, the double shaft shredder operates by feeding material into the hopper, where it is grabbed by the rotating blades of the two shafts. The material is then cut and torn apart by the shearing action of the two rotating shafts. This process is generally faster and more efficient for larger, more resistant materials, although it produces a less uniform particle size compared to a single shaft shredder. The double shaft shredder is also more resistant to jamming, making it more reliable in challenging environments.